Kiefel goes Fiber

We had the vision to produce packaging from renewable raw materials based on our thermoforming expertise. It was to be an alternative to plastic. There are ambitions and convictions behind this big project. The approach of using natural fibers to create packaging is an important topic for us, not least for reasons of sustainability.

“Fiber is the future”,

… says Stefan Julinek, technician and part of the new fiber management duo. “I have children myself and also grandchildren. The question of what to leave to our descendants is becoming more and more urgent. That’s why it’s important to take care of our planet.”

For us, fiber is a sustainable material for the future, and its application is still at an early stage. “There is still a lot of potential in material development.” Cornelia Frank, part of the Fiber leadership duo, takes a similar view. We see the work on sustainable packaging and the machines that can implement it as a wide-open field to design and create. Sustainability runs in our veins. That’s what drives our team: to ask how things can be made better. We are constantly rethinking product design and functionality, materials and composition with our customers. We want products to be easier to transfer to the circular economy. That is why we have now expanded our material expertise to include natural fibers.

Entrepreneurship & support at all levels

Cornelia Frank, Global Director Fiber Packaging, especially emphasizes the entrepreneurial spirit that prevails in our small development team. Here, challenges are tackled fearlessly, and innovations are targeted. “Just do it and test it. That’s the only way to come up with really creative, new ideas that shake up the market and move us forward.” The Fiber team can fully rely on the support of the Kiefel management; the entire Kiefel team is pulling in the same direction.

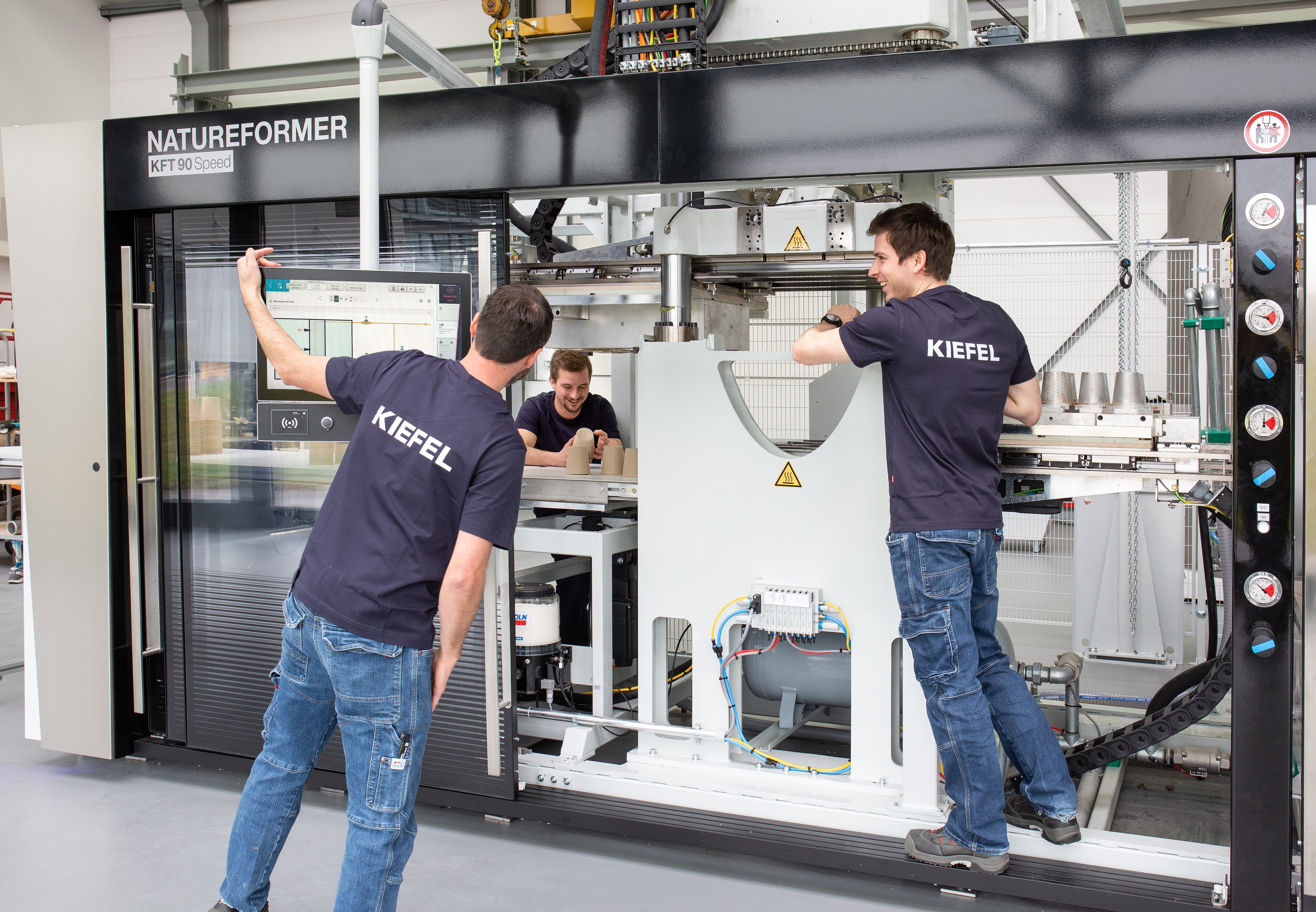

In the beginning, the work was done in addition to the daily business. The economic potential and also the special properties of natural fibers should be staked out and determined. In record time, we succeeded in creating the technological basis and prerequisites to set up a first test plant.

The milestones we have reached speak for themselves:

- 2018 Start Fiber Thermoforming

- 2020 Project start of various large-scale projects in the food sector

- 2020 Integration inline punching machine

- 2021 Fachpack – first KFT Lab exhibited

- 2021 Conversion of Packaging Technology Center & creation of a Material R&D Center – focus on fiber

- 2022 Fiber Thermoforming is established as a separate division at Kiefel

- 2023 Launch new model KFT

Breaking new ground

Fibre captures our professional ambition. The urge to explore new avenues and achieve breakthroughs in this field inspires everyone who understands the subject a little. Matthias Hausmann, Head of Central R&D, knows this topic very well and sees a lot of potential in it. “We are still a long way from the end. We can still work much more sustainably with natural fibers.” From a technical point of view, there is a wide range of possibilities and opportunities here for using natural fibers and using them even more effectively as a packaging material.

Serving sustainability

For example, you can use straw, corn and silphia, which can be harvested 1 – 2 times a year and perfectly complement fibers from wood. Our work with natural fibers and thermoforming machines also means that new technical equipment is made available to the market and thus to the whole world. This opens up new ways to make packaging more ecologically sound and highly recyclable.

Hausmann points out that technical progress now makes it possible to combine technologies that enable the production of natural fiber products for many more applications. Through control and regulation technology, there are now many more options for processing raw materials. Stefan Julinek’s enthusiasm for the subject becomes even more apparent when it comes to the technical issues surrounding natural fibers. It is precisely the challenge of the new in serving sustainability that knows how to motivate him again and again. Cornelia Frank finds the appropriate closing words here: “In order for us to make our contribution, we have to enter into dialogue with, for example, the brand owners, i.e. our customers. Only together we will be able to implement the projects that will shape our industry in the future.”