Fast availability – even in challenging times

The world of packaging is changing at great speed: New customer requirements, new regulations, new technologies – it seems that everything is evolving. The topic of supply chains in particular shows how changeable the conditions can be. The disruptions to the global supply chains have made it clear to many that now is the time to become more independent, because the availability of machines and spare parts today is the decisive advantage for production. It is precisely these worries that become meaningless with the standard version of the NATUREFORMER KFT 90 thermoforming machines.

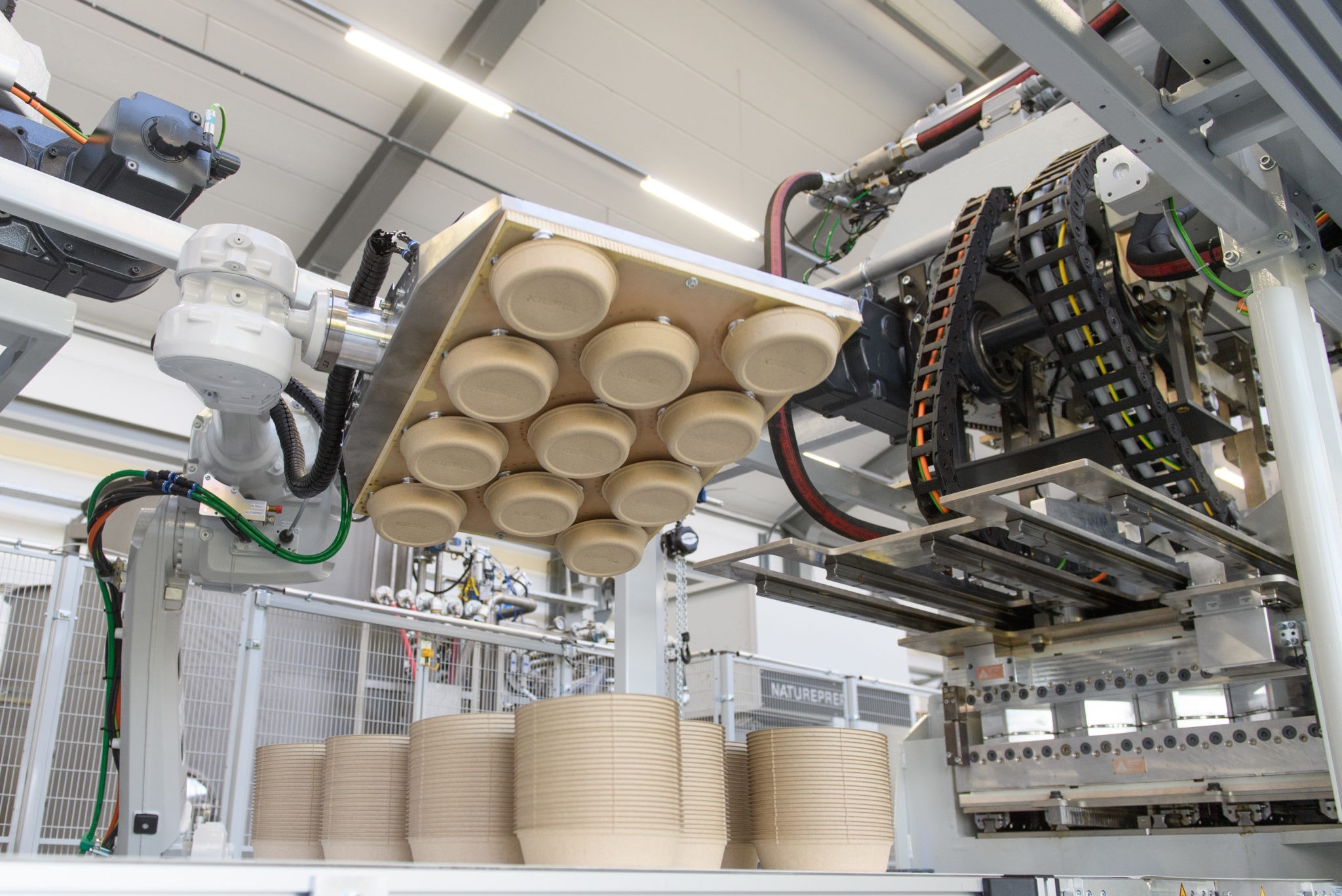

In pre-production: The NATUREFORMER KFT thermoforming machine

Kiefel customers can easily put aside any concerns that machines and spare parts might not be available in sufficient quantities, says Cornelia Frank, who heads the Fiber division at Kiefel: “We have optimized our supply chain and production to allow us to complete our machines within around two months and deliver them quickly. Or to put it another way: We are prepared to deliver. No wonder, then, that these outstanding machines have established themselves on the market and in the industry in just three years.”

One reason for the rapid availability is the cyclical series assembly based on a detailed final assembly schedule: The assembly personnel receive the material directly at the final assembly site – reduced fewer distances traveled and no more time spent searching. The synchronized provision of materials and the schedule are perfectly matched to this.

Another factor contributes to the high speed: The standardized commissioning process already takes place in production. Checklists with all test points in the correct chronological order help with this. Last but not least, interfaces have been minimized as far as possible throughout the process in order to ensure that the machine is available more quickly.

Full flexibility

The NATUREFORMER KFT thermoforming machines impress with their technical capabilities: Full flexibility through the use of natural fibers and product heights of up to 160 mm with a forming area of 900 x 600 mm are properties that matter.

And: Machine uptime is also extremely high during operation. We reduce downtimes through defined tool positions for maintenance, cleaning and tool changes. Yes, the manual tool change on the NATUREFORMER KFT is not only quick but also ergonomic, taking only about two hours. This outstanding property enables an efficient and needs-oriented conversion of the finished product.

Flexibility first

The tools of the NATUREFORMER KFT 90 can therefore be adapted to new developments. This enables our customers to react to changing market requirements within a short space of time. In addition, the KFT 90 can be configured with or without a punching function, depending on your requirements, and can therefore be modularly expanded to match the product.

Another advantage when it comes to flexibility: The NATUREFORMER KFT thermoforming machines are suitable for both large and small series production. This allows customers to react agilely to market requirements and even save storage costs.

“By the way”: We support our customers in product development in a very practical manner with our “Proof of Concept” offer.

Reduced use of materials, wide range

Kiefel’s machines require around 20% less material than competitor systems, and the materials can even be sourced on-site – i.e. locally. This avoids long, expensive and unreliable supply chains and is also more sustainable.

The new, optimized advanced version of the KFT 90, can even achieve 30% more output at the same time.

Although Kiefel is not a supplier of the material to be processed, we work closely with well-known quality suppliers. Thanks to the excellent cooperation, we have gathered a lot of knowledge and know-how about the fiber materials. Accordingly, we can provide reliable advice on which materials can best be processed by the NATUREFORMER KFT thermoforming machines.

It is important to know that, in principle, a large variety of available natural fibers can be processed and can be obtained from various production countries worldwide such as Sweden, Finland, France, Portugal, Austria and Germany. This includes pulp – bleached and unbleached in the form of long and short fibers –, CTMP (Chemical Thermomechanical Pulp) and recovered paper (PIW/post-industrial waste). In addition, various annual plants, such as silphium, or in perspective many other natural fibers, such as plant residues, e.g. from Danube reed grass and miscanthus, can also be processed. These possibilities in particular will open up many options for the use of local resources as material of the future – depending on the countries in which the NATUREFORMERs are used for production.

Quality „Made in Germany“

“An important reason for many of our customers to rely on Kiefel for the packaging of the future is the fact that we produce our machines in Germany,” explains Cornelia Frank. “However, thanks to our platform companies, for example in the USA, and our broad global Kiefel network, we are close to the customer everywhere.

Speaking of short distances: Anyone who wants to convince themselves of the advantages of the system and the high availability whilst taking a look at our production facilities is invited to visit us for a tour.” The invitation, Cornelia Frank continues, also applies to that Packaging Technology Center and Kiefel’s Material R&D Center. Facilities dedicated exclusively to the question of how packaging and material can be further optimized. So: Welcome to Kiefel! Welcome to short supply chains! Welcome to greater flexibility!