Fiber Thermoforming requires a wide range of different raw materials. Kiefel’s complete package takes care of the qualitative stock preparation and thus covers the entire production process.

Natural fiber packaging

The wishes of customers are rarely as clearly stated as when it comes to packaging: sustainability is an essential component. Our modern thermoforming technology offers the possibility to process a wide range of materials. You can choose from classic, recyclable plastics such as rPET, bio-based materials including PLA or even natural fibers – Whatever your choice, Kiefel has the right machine, tool and automation solution for you.

The wide range of raw materials that can be used for this purpose in the field of natural fibers gives you full flexibility. You will not only receive a high-quality packaging, which is exactly tailored to your individual design wishes, but also a packaging solution that offers optimal protection for your product.

BACKGROUND, INTERESTING FACTS AND ADDITIONAL INFORMATION

Interview with Richard Hagenauer - Head of Product Management Fiber Packaging What's new in the Kiefel Fiber Thermoforming world? At this year's Interpack [...]

The world of packaging is changing at great speed: New customer requirements, new regulations, new technologies - it seems that everything is evolving. [...]

We had the vision to produce packaging from renewable raw materials based on our thermoforming expertise. It was to be an alternative to [...]

Join us on the journey from raw material to natural fiber packaging. Scroll to explore

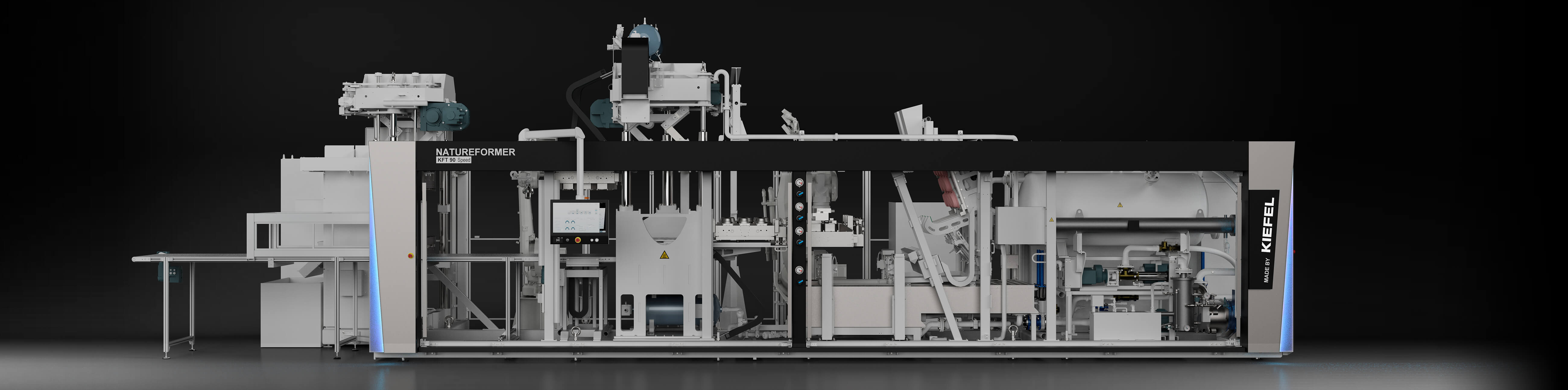

The over goal is clear: packaging must become sustainable. With the Naturformer KFT, this goal is within reach. This is achieved with a machine of outstanding performance.

Whether waterproof, biodegradable, or optimal product protection: With thermoforming all doors are open to your product ideas. From food to technical packaging, everything is possible.

Expertise, research and development are the cornerstones of our work. Our Packaging Technology Centres as well as our Material R&D Centres are dedicated exclusively to the question of how we can optimise packaging and material. This knowledge can also be at your disposal.

EXPERT KNOWLEDGE IN SMALL BITES

Fiber Thermoforming requires a wide range of different raw materials. Kiefel’s complete package takes care of the qualitative stock preparation and thus covers the entire production process.

EXPERT KNOWLEDGE IN SMALL BITES

For us, that means a commitment to sustainability and the promise of materials, product to machinery to technologies that strive for the greatest possible environmental compatibility. We always act with the aim of reducing waste, reusing recyclable materials, and recycling used materials.

Click the button below to load the %name% content.

Natural fibers, such as agricultural waste, bagasse, flax, silphia, pulp, etc.

Beverage cups, bowls, clamshell boxes, flower pots, etc. available in different sizes and materials.

Product and transport protection for electronic devices, inlays for drugstore items, and more.

Click the button below to load the %name% content.

Click the button below to load the %name% content.